Worker guidance for highest quality in bogie revision

During the mandatory inspection of bogies, different maintenance work is due depending on the condition on delivery. For this purpose, photos of all relevant assemblies must be taken at goods receipt for further coordination with the customer. It often turns out that further safety-relevant measures are necessary in addition to the required work. The affected assemblies are disassembled and overhauled in various departments or replaced if necessary. All parts are then reassembled so that safety and quality can be guaranteed for another million kilometers.

What does PG do?

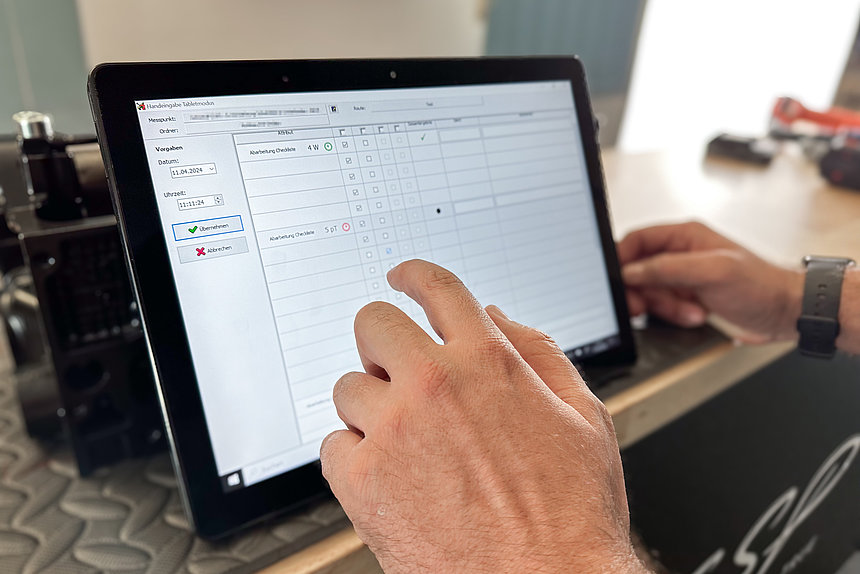

PG is a visual assembly assistance system (comparable to a navigation system) that guides your employees step by step through the entire process chain across different departments by means of on-screen instructions. All work steps are transparently displayed with photos or 3D graphics. This not only saves you time and money, but also increases the quality of the entire workflow. We are currently expanding the worker guidance to multilingualism, so that the software can be flexibly adjusted to the native language of the respective worker.

All advantages

- Error prevention through visual guidance

- Manufacturer independence

- Overview of all processes

- Simple compliance with legal requirements

- Audit-proof archiving

- Flexible application in all areas

- Simple data exchange

- Fast display of work processes

- Improvement of product quality

- Error rate close to zero

- Time and cost savings

- Low training effort for employees

- Safe processes

New features

- Automatic generation of the tree structure

- Marking of relevant jobs

- Templates for recurring jobs

- Photo templates for documentation

- Flexible label printing for handover

- Language selection (UI and customer texts)

- 2-language reports

![[Translate to en:] [Translate to en:]](https://www.csp-sw.com/fileadmin/_processed_/4/0/csm_Blogbeirag_Eduard_im_Beirat_80166e698c.jpg)