QMS matters - Quality assurance in battery production

![[Translate to en:] [Translate to en:]](https://www.csp-sw.com/fileadmin/_processed_/f/4/csm_2024_qms_matters_batteriefertigung_4176a9e00b.jpg)

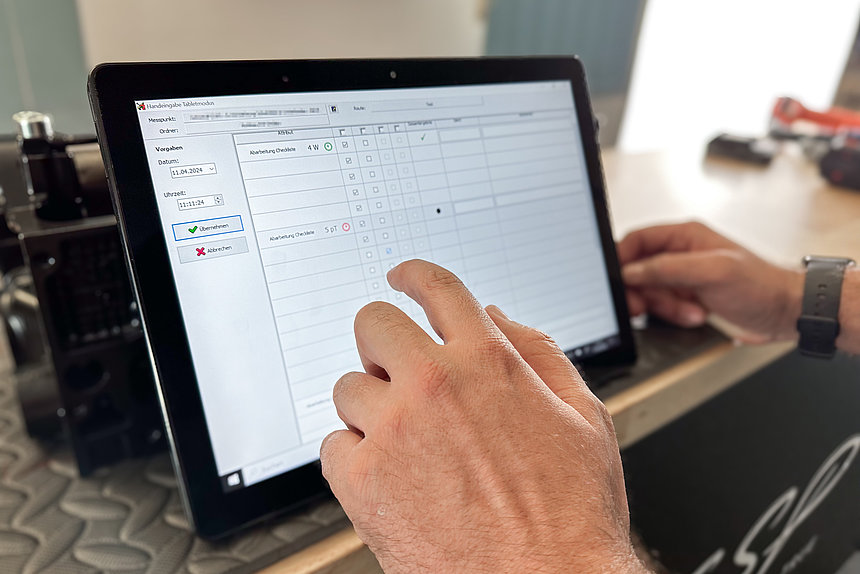

How modern battery production benefits from quality assurance

As a manufacturer of quality assurance software, our mission is to offer innovative solutions for the challenges of modern industry. Matthias Sextl, our Product Owner for IPM, sums up why quality assurance is crucial in battery production:

"Modern, highly automated battery and high-voltage storage productions bring one or two challenges with them. Large component structures have to be mapped and correlated with the associated quality data. At the same time, in the single-digit cycle time range, it must be ensured across all processes that all work steps have been carried out successfully and that quality standards and safety are therefore guaranteed. For this and many other challenges of automated lines, IPM offers many tools to manage them effectively."

Our software solutions support companies in mastering these complex requirements by enabling comprehensive quality assurance in real time. With IPM, you can increase efficiency and reduce errors while ensuring the highest quality standards in battery production.

Find out more about how our QMS solutions can help optimize your production processes and increase your competitiveness.

![[Translate to en:] [Translate to en:]](https://www.csp-sw.com/fileadmin/_processed_/4/0/csm_Blogbeirag_Eduard_im_Beirat_80166e698c.jpg)